A hoist is the lifting component of an overhead crane, designed to raise and lower loads with control and precision. Hoists can be classified by their lifting medium (chain or wire rope), or by their power source (manual, electric, or pneumatic). Each type has distinct features, capabilities, and applications.

Selecting the right hoist is critical for safety and efficiency. With various types available, understanding the factors to consider, benefits, and ideal applications of each can help you make the most informed decision. Below is an overview of the main hoist types, their features, and the environments where they perform best.

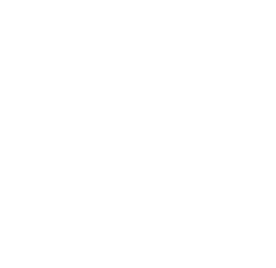

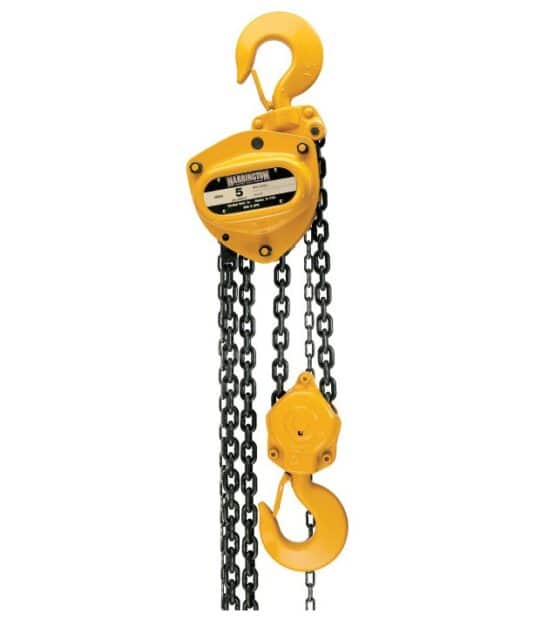

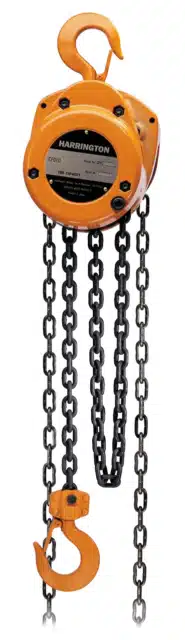

Manual Hoists

Manual hoists rely on human power to operate which makes them a practical solution in areas where electricity is unavailable. These hoists are known for being cost-effective, portable, and compact, making them ideal for tight workspaces and occasional lifting tasks.

Operated by either pulling a hand chain or using a level mechanism, their simple design requires minimal maintenance, and they are best suited for lighter and low-frequency use.

Common applications include construction, maintenance, automotive repair, rigging, general manufacturing, and use in remote or hazardous environments where powered options are not feasible.

Electric Hoists

Electric hoists operate using a motor that drives gears to lift or lower loads using either a chain or wire rope. These hoists provide faster lifting speeds, precise control, and reduced physical strain on operators compared to manual options.

Electric hoists are powered by electricity and typically controlled using a push-button pendant or radio control. Available in both chain and wire rope configurations, electric hoists are ideal for applications requiring consistent and efficient lifting. However, they are limited by their duty cycle, meaning the motor must cool down between uses to prevent overheating.

Electric hoists are commonly used in manufacturing and assembly lines, power generation facilities, and other industrial operations where repeatable and accurate lifting is necessary.

Pneumatic (Air) Hoists

Pneumatic hoists, also known as air hoists, operate using compressed air to power their motor, allowing for continuous use without the risk of overheating. This makes them well-suited for high-cycle, demanding environments.

Pneumatic hoists have a spark-resistant design which enhances safety in hazardous or explosive locations, while variable speed control allows for controlled lifting. These hoists also offer higher lifting capacities, making them a reliable choice for heavy-duty applications.

Commonly found in automotive assembly lines, warehouse and distribution centers, and in industries such as oil, gas, chemical, and mining, these hoists perform well in environments with frequent starts and stops of extreme heat.

Chain Hoists vs. Wire Rope Hoists

Chain Hoists:

- More compact, portable, and easier to install

- Generally located in smaller work stations, factories, and assembly lines

- Better suited for lighter loads (typically under 5 tons)

- Lower maintenance requirements and longer service life in certain applications

- Generally less expensive

Wire Rope Hoists:

- Smoother and quieter operation

- Capable of higher lifting speeds and greater capacities (often over 10 tons)

- Better suited for production environments and severe-duty applications

- Well-suited for high-frequency and extended lifting operations

Hoist Solutions from Engineered Systems

At Engineered Systems, we offer a full range of manual, electric, and pneumatic hoists from leading manufacturers. When deciding between hoist types, consider the capacity requirements, headroom limitations, frequency of use, environment, and power availability. Our team of experts will work with you to determine the right solution for your application.

Contact us today to learn more about our hoist options and find the best fit for your lifting needs.